Quick Menu

Home Machining

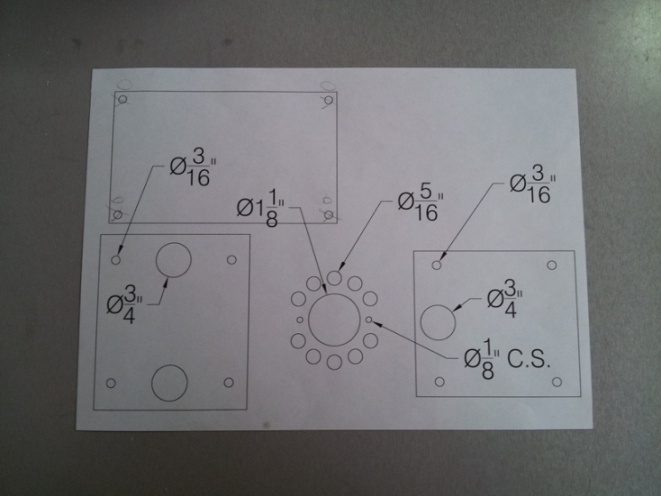

Step 1

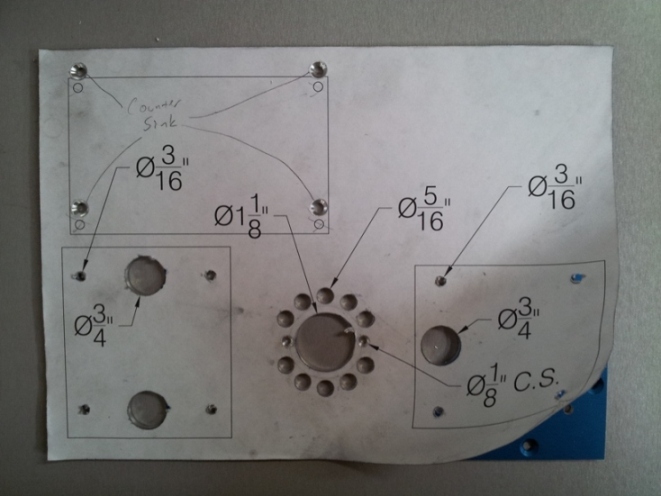

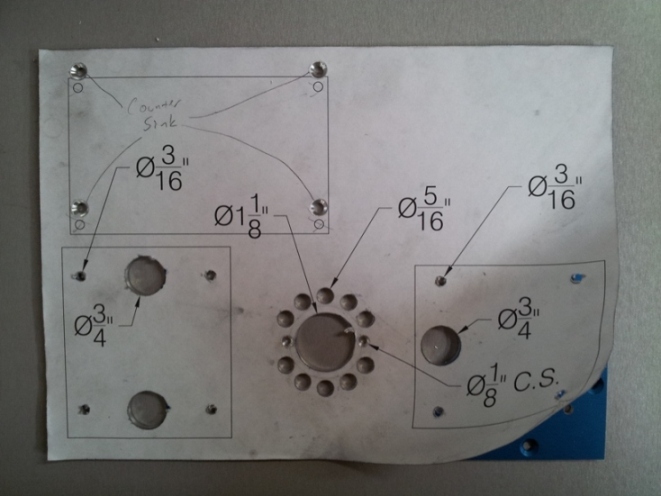

Using some paper, print or draw your layout. Tip: make the hole center marks as small as possible but still visible. This helps reduce positional errors.

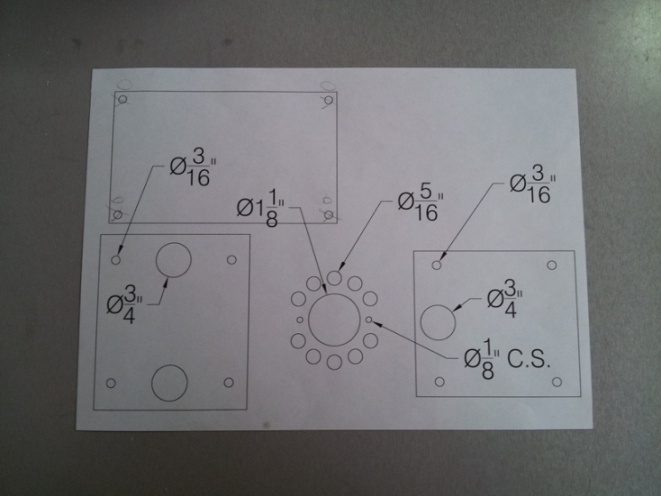

Step 2

Use the Krylon® Easy-Tack™ glue pictured below (or a similar adhesive) to attach the paper to the piece of material that is being worked. This glue is a repositionable adhesive and makes this process simple and clean with no mess.

Be sure you let the glue dry on the paper first before placing it on the material.

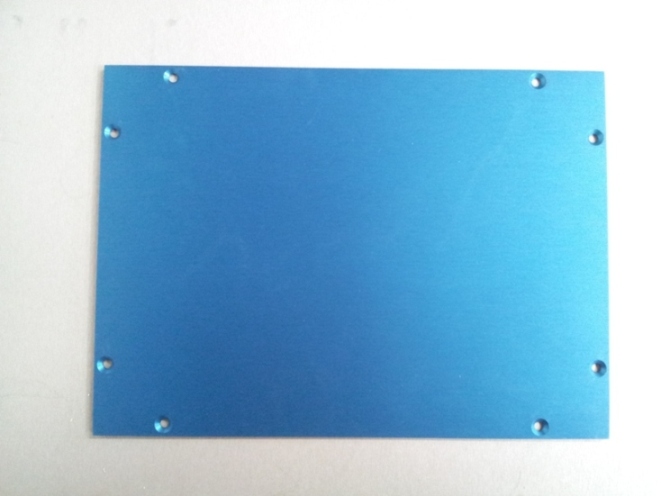

Step 3

Apply paper with dried glue to the piece being worked. Use a center punch to mark the center of each hole. This will help keep your drill or cutter from drifting. Now drill or cut your holes.

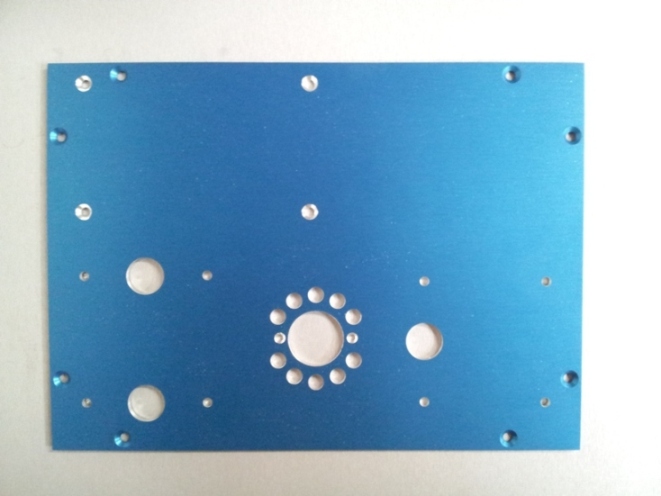

Note 1

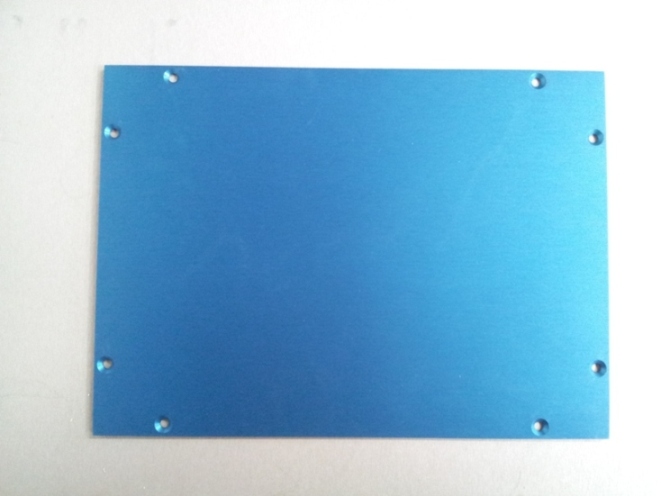

See how the material is not damaged by the drilling. The paper protects the surface and is easily removable after completion.

Note 2